Research Aims to Prevent Infections

Julie Bitely

| 3 min read

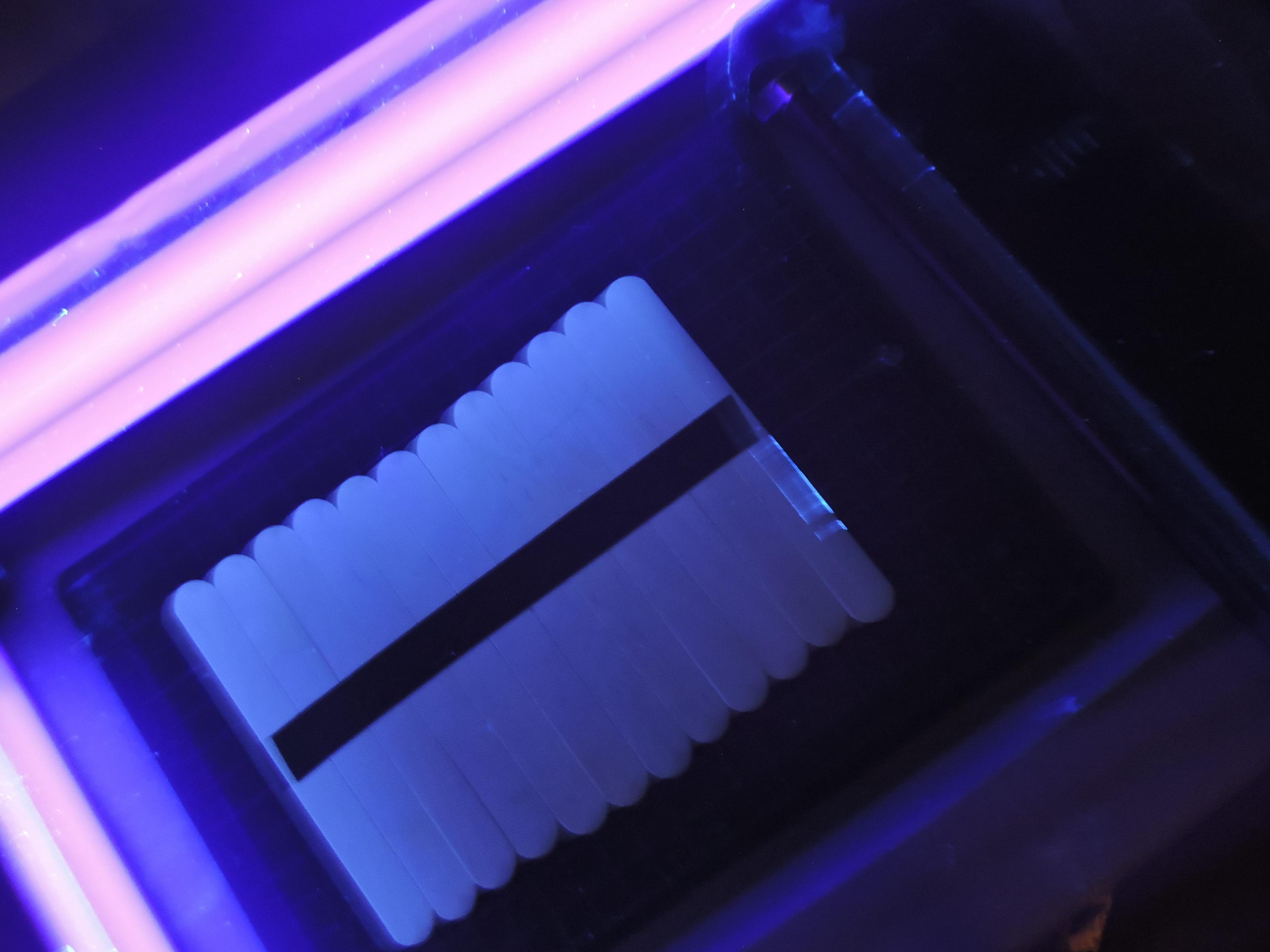

Black lights may conjure up a party vibe, but their use in a Michigan State University (MSU) research project is detecting a serious problem. While medical professionals are diligent about maintaining a clean and sterile environment, on any given day, about one in 25 hospital patients has at least one healthcare-associated infection, according to the U.S. Centers for Disease Control and Prevention. Using sterile instruments and medical devices is critical, however, inadvertent contamination from the packaging they’re housed in could be putting patients at risk. That’s where professors Tamara Bush and Laura Bix come in with their black lights. Along with a team of research students, they’re working to improve upon a commonly used type of pouch packaging, which is opened by pulling two sides apart. The team is also looking at how opening techniques can be improved to reduce contamination. Their research is being funded by the Blue Cross Blue Shield of Michigan Foundation. In an operating room, the device or equipment inside the packaging is sterile, while the outside of the package and the gloved hands opening it are not. The trick for medical professionals is to open the package and slide the device or tool onto the sterile operating field without letting it touch either your hands or the exterior of the package.

GVSU student Hayley Woodward participates in a research session held in Grand Rapids. In their research, three sets of eight packages are opened by health care professionals and students with training and practical experience. Participants come from MSU, Lansing Community College (LCC), Grand Valley State University (GVSU) and local hospitals. The back of their gloved hands are coated in Glitterbug lotion, which glows under a black light. The outside of the packages are also coated with the lotion. Cameras capture the movements of their hands as they open each package. The first set of packages contained an exploratory design, with half made to be difficult to open and half requiring less force. The second and third sets of packages were identical, containing both a design with a tab to open and a design made with material that curls out. The difference between the second and third set of packages was the direction provided to those opening them. Study participants opened the second set using the technique they’d learned in school, while they were instructed to open the packaging in one fluid motion, to reduce the amount of handling, for the third set. After a successful open, there shouldn’t be any lotion on what’s inside the package; its presence would suggest that the device being transferred had come in contact with a nonsterile surface. (In the image at the top of this post, you can see lotion residue glowing on the right side of the tongue depressors that were in a package.) Early data suggests that standard packaging may result in higher rates of contamination. The packaging designed with material that curls out and guided instruction to open the package in one motion seems to be making a positive difference. Bush and Bix plan to publish their research when it’s complete. Ultimately, they hope the study can drive change in package design and lead to more comprehensive training about the importance of opening techniques and their effect on contamination. “Even making a small change in one area and affecting it is going to have an impact,” Bush said. If you enjoyed this post, you might also like:

- Why Improved Medical Device Labels Could Improve Patient Safety

- Got Grants? Tips for Applying to the Blue Cross Blue Shield of Michigan Foundation

- Report Highlights Quality Improvements in Michigan Hospitals

Photo credit: Julie Bitely